Wondering how to increase employee engagement?

Your efforts will only make an impact if you can reach employees where they are. An unprecedented 83% of Axonify users log in to train 2-3 times a week.

Improve the employee experience (and boost morale) by helping them fit in fast, investing in their performance and growth, and keeping the lines of communication open—all through an employee engagement tool they love to use, so you can feel confident your efforts are creating a more engaged workforce.

Improve the employee experience by turning the onboarding firehose to laser-focused. Keep it short and zoomed in on only the things they need to know to feel confident performing in their new roles.

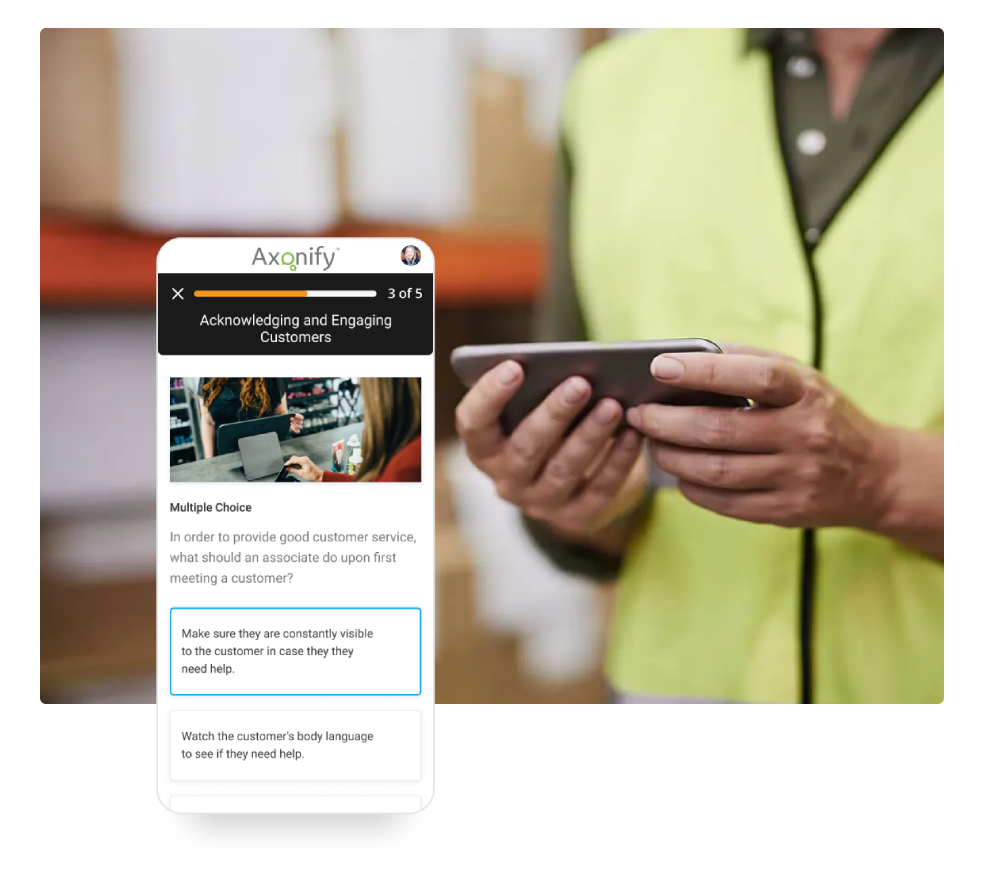

Deliver fun, personalized bursts of training content with employee engagement software right in the flow of work, on the devices that work best for them. Plus, get meaningful insights about engagement data and employee feedback to help determine what’s working and what isn’t.

Help them understand their role in bringing your brand promises to life with consistent, clear employee communication and performance management delivered in the same employee engagement platform they train in every day.

Boost engagement and employee satisfaction by turning onboarding from firehose to focused. Use Axonify’s employee engagement solutions, like learning paths, reinforcement and continuous learning, to simplify the onboarding experience and improve employee engagement while protecting your bottom line.

Your efforts will only make an impact if you can reach employees where they are. An unprecedented 83% of Axonify users log in to train 2-3 times a week.