Take this guide on the go!

Get the PDF edition of this guide in your inbox.

Best microlearning platform.

Award-winning microlearning platform.

Mobile microlearning platform.

You’ve no doubt heard vendors describe themselves in one of these ways. You’ve heard thought leaders referring to microlearning in their talk tracks. Maybe you’ve even been asked by executives to implement it. But you probably haven’t found a simple, consistent definition for microlearning.

Is it just a lot of hype, or is it really a transformative concept? And how can it help you get measurable results from workplace learning? We wrote this guide to help you separate the hype(ful) from the helpful.

Here’s the truth: when done right, microlearning can help solve some of your biggest business challenges and have a profound impact on employee performance and organizational success. You can apply microlearning to increase sales, reduce safety incidents, improve customer service, decrease turnover and achieve any other business objective that’s driven by people’s knowledge and skill.

This big promise comes with a big caveat: microlearning is not just about serving up short training content.

Yes, it’s important to keep your training bite-sized and quick to consume. But giving your employees a bunch of short videos to watch isn’t going to help them change their on-the-job behaviors in meaningful ways.

To achieve the benefits of microlearning, it must be part of a holistic approach to modern learning that begins with mapping out your business goals then applies the latest in technology, brain science and solution design principles. This is the winning formula for getting business results that you can measure.

So, whether you’re an experienced learning practitioner looking to up your game, an HR professional who wants to keep turnover low and engagement high or a senior business leader trying to solve a critical operations problem, consider this your ultimate guide to microlearning that actually works.

Let’s dive right in.

Get the PDF edition of this guide in your inbox.

A note on frontline mentions in this guide

As you read through this guide, you’ll notice frequent mentions of frontline workers. That’s because we focus on using microlearning plus other key principles to give frontline employees the right-fit experience they need to perform their best at work every day. But even if you don’t support a frontline workforce, you’ll find lots of useful information in this guide. You can easily apply the concepts to any workforce.

How microlearning fits into a modern approach to frontline training

4 trends influencing the need for a shift in how we view microlearning

Advantages of incorporating microlearning into your modern frontline training strategy

Designing your microlearning-based frontline training experience

How to create your microlearning strategy

Best practices for building microlearning content

How to evaluate a microlearning solution

How real-life organizations are using microlearning within a modern training framework

Tips for starting your modern learning transformation

Before we explore the definition of microlearning, we need to pause and clarify what it is NOT. Like any big trend, microlearning is surrounded by lots of myths and assumptions. Some of these come from misunderstandings and confusion among various professionals about how it really works. Others are born from vendors who want to capitalize on the trend but without any real depth or value. Whatever the reason, misconceptions have rapidly and thoroughly cluttered the real value of microlearning. So, let’s correct that, shall we?

Not true. In fact, microlearning’s been around a long time. It got its start in cognitive science. And, in recent years, it’s just been labeled differently. (Do the terms “bite-sized” or “chunked” sound familiar?)

While it’s obvious that microlearning content should be short, the duration isn’t as important as the focus. Frankly, a lot of traditional content in learning solutions includes too much fluff. But microlearning is the opposite. It homes in on the most important info employees need to know to change their behavior and reach a specific goal.

The use of video in training has exploded over the past few years thanks to technological improvements. Just 10 years ago, you needed a sizeable budget, heavy equipment and professional help to produce a simple video.

Today, high-quality content can be created with just a smartphone and a laptop. This makes video a great format for microlearning content, but it’s also not the only format for microlearning content. (Also, simply breaking up one long video into a series of short videos isn’t microlearning either. Sorry.)

As with any training content, the medium should match the message and context in which it will be consumed. Think beyond video with things like pop quizzes, quick tips, blogs, podcasts, infographics, job aids, question-based learning and more.

It doesn’t matter whether the content is cut and dry or more of a brain-bender, microlearning can work for any topic. You just need to use it in the right way, at the right time. This means your organization needs to know the problem it’s trying to solve and apply the fundamentals well:

Regardless of the topic, training is training. When and how microlearning is introduced may shift. The types of content may change. But microlearning principles are equally applicable to all workplace topics.

Classes aren’t going away. eLearning won’t either. And coaching definitely isn’t going anywhere. Microlearning isn’t an all-or-nothing proposition. While it might replace some of your existing approaches, think of it as an important part of your toolkit. It’s meant to fit into your overall training strategy to help you get the best business results.

There is a tremendous push in workplace learning to enable employees to own their development by engaging in self-directed learning. This can be a good thing, as long as we acknowledge that people don’t always recognize their own weaknesses (Dunning-Kruger Effect).

In addition to personal learning and development needs, organizations continue to evolve priorities as well. So, effective workplace learning is a balance of push and pull. Microlearning enables this balance by increasing employee performance support touch points and sustaining knowledge increases and behavior change long-term.

It doesn’t matter if you’re 22 or 62 (or any age in between) microlearning meets the unique needs of all employees—regardless of demographics. In fact, when done right, it’s proven to help everyone learn and boost long-term memory. Remember when we said microlearning is all about focus? Well, that means it’s great for helping management focus on specific results and adapt to the needs of each individual. How great is that?

Before you go all-in on microlearning, it’s important to understand exactly why microlearning is such a powerful and sought-after strategy. Workplace training is littered with vague buzzwords and shiny new tools. It’s easy to make uninformed decisions when you have a mandate to improve your skill development opportunities and solve high-priority business problems.

But when you combine focused micro-content with the right principles, you drive better performance and outcomes across every industry and use case. That’s why it’s critical that you understand the fundamentals—so you can apply them in the right way from the beginning and quickly get results that will turn heads.

Yes, microlearning delivers content in short, focused bites. But to actually be effective, microlearning should also:

When you put all of these things together that’s when the magic happens—you get employees consistently doing the things that impact specific results the business really cares about.

Microlearning content is focused on the moment of need, helping employees target the most critical information required to do their jobs. This is how people learn and solve problems in everyday life, which means the microlearning experience is more familiar and comfortable for employees.

If you want to implement a solid frontline training strategy that positions every employee for success, your microlearning strategy must include these five principles.

We definitely don’t want to play favorites but, out of all the fundamentals we mention, this one tops the list. There’s no getting around it. Microlearning must focus on a single problem, not an unmanageable pile of interconnected issues. If you can’t identify a clear, measurable business objective you want to achieve, then just stop right here. (Think specific, like boosting customer satisfaction scores by 50%, or increasing loyalty card sign ups by 25%).

After you know what your goals are, it’s time to get into the nitty-gritty details of the actions employees will be expected to take in order to achieve them. This starts with understanding the behaviors your employees need to demonstrate on the job, then you can outline the knowledge they will need to get there. Bonus: this helps you separate need-to-know information from nice-to-know.

Maybe ladder accidents are on the rise. If so, employees would need to learn things like:

a) How to inspect a ladder to ensure it’s safe to use.

b) The proper steps for climbing a ladder.

c) Which ladders to use in specific situations.

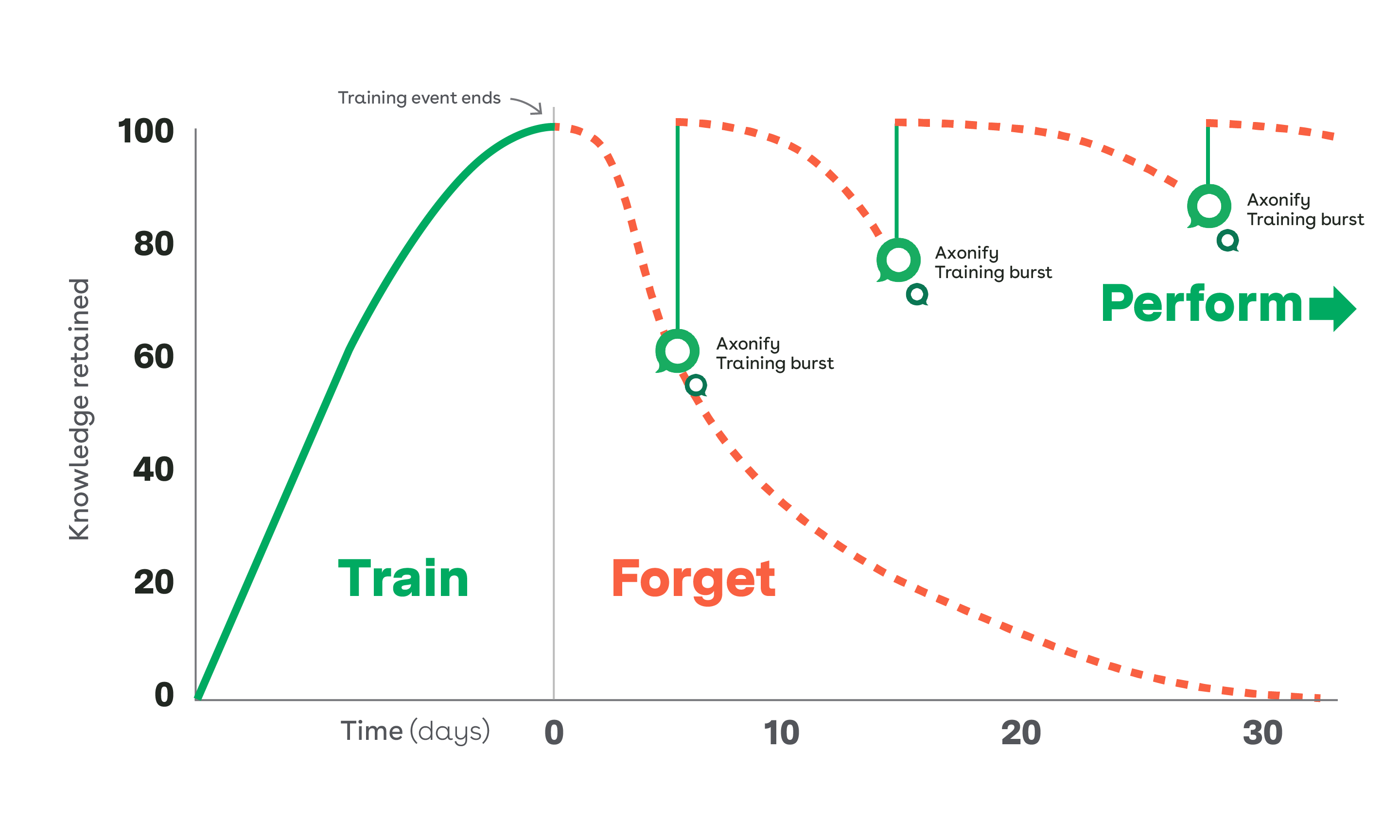

Let’s be honest: If employees can’t remember their training or how to apply it on the job, it’s a waste of time and money. That’s where brain hacks come in. Ever heard of the forgetting curve? It shows that people forget 90% of what they learn within 30 days if it isn’t reinforced. That’s why effective training applies proven brain science, including

a) Spaced repetition – Practicing a new topic repeatedly over a period of time to deepen memory.

b) Retrieval practice – Using questions to strengthen memory by forcing the brain to recall information.

c) Confidence-based assessment – Measuring an employee’s expressed confidence in a topic to improve memory and self-awareness.

No question, employees are swamped these days. They’re asked to know more, do more and deliver more—often without any added support. It’s even worse for frontline workers, like sales associates, field service workers, delivery drivers and contact center agents. Taking them off the floor to sit through hours of training is a scheduling nightmare. And what manager wants to handle the fallout from lost productivity time?

The most effective training fits into employees’ day-to-day workflow without pulling them away from the places they need to perform. By tapping into existing tech they use on the job (like mobile devices and point of sales systems), it’s easy to deliver training to employees in just a few minutes each day. And, with information always at their fingertips on these devices, it’s just as easy for them to do a quick lookup when they have a question. The result? No more guessing when it comes to figuring out the correct actions to take on the job.

Feeling limited by test scores and completions? Not anymore! Microlearning helps you collect a boat load of meaningful data as employees engage in training activities almost every day. You’ll glean insights into the types of content they consume, the information they know and don’t know and if they are able to apply that knowledge correctly on the job. And with all this information, you can directly connect how training impacts the business objectives you outlined at the start. Not making the right progress? You’ll know sooner, so you can pinpoint trouble areas and proactively adjust training to hit your planned targets.

Business has changed dramatically over the past few years. Unfortunately, workplace learning hasn’t always kept up. Here are four trends that make microlearning the ideal fit for modern organizations.

A product recall. A new technology. A worldwide pandemic. Even small changes can have huge repercussions in our hyperconnected world. To stay ahead, organizations must keep a finger on the pulse and be ready to shift in an instant. Employees must also stay on top of changes or risk being left behind. But, with ever-growing demands on employee time, it’s nearly impossible to complete all their to-dos, let alone squeeze in time for training. Plus, managers can’t afford to take frontline employees out of the operation for hours or days. An organization can only evolve as fast as it’s employees can learn. But where can people find the time?

This is why microlearning makes so much sense. It’s agile and quick. It’s proactive, not reactive. So, when it’s time to change, it’s easy to adjust existing content or create new material. Plus, it fits seamlessly into the daily workflow. Employees can get up to speed fast without hurting productivity.

Who doesn’t want to know how to brain hack their way to excellence? While this kind of research used to be reserved for PhDs, books like Make it Stick, Brain Rules and How We Learn have made it easier to wrap our heads around these complex ideas. “Brain science” is now a well-known concept. And business leaders are on the hunt for ways to embed proven cognitive practices into their corporate strategies to get results. It doesn’t take a scientist to figure out why this is a smart thing to do. That’s why rooting your training approach in learning science is the perfect solution.

Technology is rapidly changing how work is done. Automation is shifting employee development to focus on more human skills, such as collaboration, problem solving and customer service. Mobile devices allow employees to quickly access information whenever and wherever they need it.

BYOD (bring your own device) is quickly becoming a reality for corporate and frontline workers. On-the-job devices, from point of sale systems to handheld scanners to deli scales, are now internet-enabled. Wi-Fi is an expectation in public spaces, and 5G is eliminating bandwidth restrictions. When pieced together, all of this technology has exponentially expanded employee access to learning and support on the job.

Many organizations are just starting to explore these innovations. But our always-on, mobile-everything environment means employees should never be more than a few clicks or swipes from the answer, just like they are at home. Plus, when they’re already using internet-enabled devices to do their jobs, it’s easy to consume a burst of microlearning every day.

Customers expect employees to know. It doesn’t matter when the product was released or how complicated your operation has become since you introduced e-commerce, curbside pickup and home delivery. Your customers expect your employees to always have the answer. Your teams need (and deserve) right-fit training and support so they can meet these expectations and bring your brand promise to life.

We’ll send our PDF edition of The Ultimate Guide to Microlearning to your inbox for later.

Most of us have been conditioned to believe there is a place and time for learning. We’ve gone to school and sat in rooms for hours at a time. At work, we’ve been scheduled for classes and all-day workshops. Even digital experiences tend to have schedules and requirements. This simply isn’t how people really learn. We are learning and improving every second of every day while we engage in our daily activities.

To implement a successful modern training strategy, you need to buy into the inherent value of helping your frontline learn in the flow of work using microlearning. Here’s a list of huge advantages waiting for you on the other side of adopting this mindset.

Earlier, we stated that to take advantage of the true value of microlearning it needs to be part of a holistic training experience that incorporates some other key elements. But what does this experience actually feel like for a frontline employee in the workplace?

To achieve the benefits we’ve outlined so far, you should take a hard look at the overall learning experience you are creating for your frontline employees. Today, too many organizations provide a “spaghetti experience,” which involves building content and throwing it at as many employees as possible to see what sticks. This doesn’t benefit anyone. You waste time building unnecessary content, and your employees waste time checking unnecessary boxes.

Modern training helps you shift from a place-and-time approach to a continuous learning experience. Because microlearning fits neatly into the workflow, you can introduce new, ongoing learning and support tactics. You likely won’t get rid of all of your existing tactics. But, when you do push out a training event or online module using tactics such as knowledge reinforcement and on-demand resources will make these experiences much more impactful.

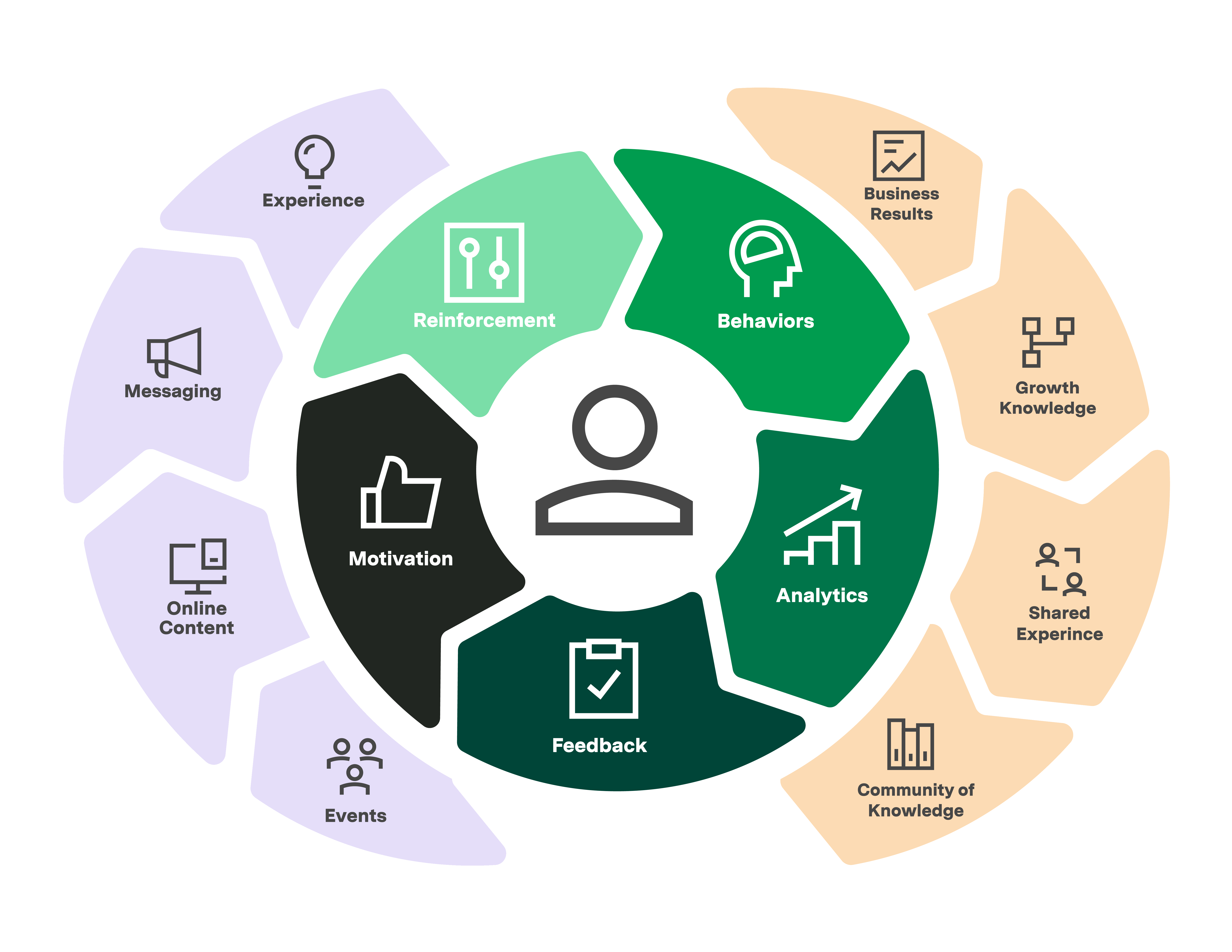

Every organization will craft a unique modern training experience based on the needs of their employees. However, this diagram shows how your tactics can be aligned to foster a continuous, right-fit learning experience for an individual employee.

Here are some real-world examples of modern training experiences that have been designed to fit microlearning and support opportunities into the already-busy day for any frontline employee, regardless of role or industry.

In a retail store, associates access training right after they clock in every shift. The training session serves up reinforcement questions tightly focused on topics that are critical to performing well in their jobs. The whole session only takes 3 to 5 minutes, then they’re ready to hit the floor confident that they’ll do the right things in the right moments.

Check out the stories included in this article for more details around the modern, right-fit training experiences organizations are creating that include microlearning.

In addition to ongoing support, a continuous microlearning experience provides you with advanced measurement and analytics opportunities. By constantly assessing what people know and do on the job, you can actually see the impact of your training programs and make adjustments before small issues become big problems. And, because the experience is targeted to the individual employee’s specific needs, the value is clear which provides motivation to engage in learning voluntarily—without being chased by a manager or administrator.

In a grocery store, associates not only take their daily burst of training, but have immediate access to on-demand job aids through their modern training platform. This allows them to look up important information in a few clicks, right in the moment of need.

Check out the stories included in this article for more details around the modern, right-fit training experiences organizations are creating that include microlearning.

In addition to ongoing support, a continuous microlearning experience provides you with advanced measurement and analytics opportunities. By constantly assessing what people know and do on the job, you can actually see the impact of your training programs and make adjustments before small issues become big problems. And, because the experience is targeted to the individual employee’s specific needs, the value is clear which provides motivation to engage in learning voluntarily—without being chased by a manager or administrator.

In a retail banking environment, frontline workers watch a short video on the credit card pre-approval process once, and then answer a few questions about the content every time they log on for the day. The short bursts of reinforcement give them increased confidence when cross-selling to clients.

Check out the stories included in this article for more details around the modern, right-fit training experiences organizations are creating that include microlearning.

In addition to ongoing support, a continuous microlearning experience provides you with advanced measurement and analytics opportunities. By constantly assessing what people know and do on the job, you can actually see the impact of your training programs and make adjustments before small issues become big problems. And, because the experience is targeted to the individual employee’s specific needs, the value is clear which provides motivation to engage in learning voluntarily—without being chased by a manager or administrator.

In a contact center environment, agents take advantage of a few free minutes between calls to access their micro-bursts of training that reinforce the key things they need to remember to stay in compliance with key regulations.

Check out the stories included in this article for more details around the modern, right-fit training experiences organizations are creating that include microlearning.

In addition to ongoing support, a continuous microlearning experience provides you with advanced measurement and analytics opportunities. By constantly assessing what people know and do on the job, you can actually see the impact of your training programs and make adjustments before small issues become big problems. And, because the experience is targeted to the individual employee’s specific needs, the value is clear which provides motivation to engage in learning voluntarily—without being chased by a manager or administrator.

How can you help evolve your organization from relying on place-and-time training that happens once or twice a year to a continuous microlearning experience that’s embedded within every workday?

Truth time: Evolving to a modern training approach is not an overnight transition. It requires a slow and measured evolution of your company’s mindset towards training and the role it plays in the business. Instead of just focusing on getting training over with so you can check the completion box, all your stakeholders—from executives to frontline employees—must recognize (and buy into) the importance of continuous microlearning to keep you more agile than the competition and ready for anything.

Luckily, the fundamentals we’ve discussed so far are designed with this evolution in mind. So, you’ll be able to build your case and show value quickly, then rapidly iterate and evolve your overall learning strategy.

Learn the best way to implement an effective microlearning strategy here.

We’ve established that microlearning content isn’t just short videos. We’ve also identified that it’s not simply smaller versions of the content you have been using for years. So, what is it, and how do you build it to enable continuous, targeted learning?

Too often, organizations focus on creating training content first. This approach doesn’t make any sense in a modern business. It’s easy to miss the mark on what employees really need. And the result is a collection of vast content catalogues that are expensive and almost never used to their full potential.

Before building anything, it’s important to identify the result you want to achieve. This results-first approach is a critical framework for building right-fit microlearning content.

What business problem are you trying to solve, and how will you MEASURE the results? You may have to push your peers and stakeholders to nail down as specific a goal as possible. Push the conversation towards the factors that led to this discussion in the first place. There are likely specific incidents taking place within the business that have created a need.

Let’s take a safety example. Your stakeholder may come to you with the request to improve the company’s safety culture. That sounds great, but how do you measure culture? Ask for specifics on workplace incidents that have led to the safety culture conversation. Find a measurable goal that you can address with microlearning. This effort will eventually become the foundation of a larger effort required to foster a safety culture, but your focus will remain on solving a specific problem.

To continue the example, let’s assume that back injuries are the biggest safety problem in the business right now. Reducing incidents of back injuries by 80% is now our measurable business result target.

What do employees have to DO to achieve the targeted result? What will the necessary behavior change look like when observed within the operation? You will again likely have to challenge your stakeholders to get specific when it comes to your goal. Break down the steps necessary to be successful in the selected topic.

In our safety example, you might decide that employees must perform the following actions to reduce back injuries when lifting:

What do employees have to KNOW to execute the required behaviors? Isolating this part provides you with the opportunity to separate need-to-know from nice-to-know information to keep your training focused on the result. Nice-to-know information can eventually be made available on demand, but your microlearning content will focus on just the critical knowledge required to execute the identified behaviors.

To execute a safe lift, employees must:

Now you’re ready to make a content decision. What’s the best way to share the required knowledge to drive behavior change and, ultimately, achieve the targeted result? You should be open to a variety of content format options rather than defaulting to a traditional course.

To improve knowledge and behavior related to safe lifting, employees will receive:

We’ll send our PDF edition of The Ultimate Guide to Microlearning to your inbox for later.

As you can see in our example, microlearning content can take a variety of formats. Rather than be limited to just SCORM courses, you can expand your toolkit and match the delivery method to the needs of your employees. Here’s a list of potential content types that fit the microlearning experience:

When and where will this content be consumed?

Some formats, such as video and interactive modules, may be more difficult to experience in a busy operational environment. Text-based solutions can also be consumed more quickly which lends them to on-demand knowledge needs because employees can review just the information they want rather than watching an entire video.

Which device(s) will be used to access this content?

You should maximize your technological capabilities and address any potential limitations. For example, if you’re using a point of sale (POS) device to deliver content, it may not have speakers and so would limit your use of audio within a video.

What resources are available to develop this content?

Who will be doing the work and what can they do in the time available? Questions and articles are usually easier to develop as compared to online modules and videos. Match the skills and capacity of your team with the needs of your employees.

How quickly do you need to deliver this content?

If you’re trying to solve a critical business problem, you’ll need to select a format that you can turn on very quickly. This is where video, question-based learning and job aids can be extremely useful, as they can be executed faster than a more robust module.

Remember, microlearning content is only part of the success equation. To provide the most effective and engaging experience that will also solve real business problems, you must incorporate the 5 fundamentals we discussed earlier to create a right-fit learning and support experience.

Many vendors and consultants are aligning their marketing to the microlearning trend. That’s why you shouldn’t rush into a buying decision. Make sure you take time to pause and ask the right questions to find out if an offering truly aligns to a holistic, right-fit training approach that’s going to get meaningful results for your business.

Here’s a set of questions to ask when evaluating any “microlearning” solution. The more YES answers you get, the more likely the solution will provide value to your organization.

Transformational organizations across many industries are reaping the benefits of right-fit training. Whether they’re solving onboarding, sales, product, compliance, or safety challenges, microlearning is a key strategy they use to give their frontline employees the right support at the right time to drive better performance and ultimately benefit the bottom line of the business.

Explore the real success stories of a few of these companies below.

Eyemart Express ditched their paper-based onboarding methods for a modern, quick, microlearning approach that cut their onboarding time from 35 days to 10 days—saving them thousands of dollars per employee in the process.

See how leading grocers–like Southeastern Grocers, Longo’s and Heinen’s–are using microlearning to ensure customers have consistently amazing experiences across every store.

If you answer “yes” to five or more of the above questions, then it’s time to look at what microlearning within a modern training framework can do for your business. Here are a few suggestions on where to get started.

As we explored earlier, there are a number of myths getting in the way of serious conversations around the true value of microlearning. These false assumptions have the unfortunate potential to limit the impact of microlearning. You can play an important role in helping your organization get past this hype and focus on the real meaning and value. Sharing this article with your peers and stakeholders is a great place to start when it comes to overcoming microlearning myths.

You don’t have to do this alone. Learn from the people who have already introduced effective microlearning with great results. Engage them in conversation. Find out how they overcame challenges to achieve success. Invite partners to share their stories with your teams and stakeholders so they can see just how powerful microlearning can be. Sometimes an outside voice can carry extra weight.

One of the big differentiators for microlearning as a foundational strategy is the opportunity to position learning and support closer to the employee’s day-to-day work. To do this correctly, you need a solid understanding of what this context looks like. Spend time on the frontline. Have conversations with your employees to understand the problems they face every day and how you can help them improve by applying microlearning along with the principles that make it most successful.

What keeps your CEO up at night? You should know this answer already. Even if you haven’t been assigned to solve this problem, you should understand how it impacts your organization and begin discussing how you could address it with training. An improved understanding of your business will be critical as you begin to introduce microlearning as the foundation of your modern training approach.

You likely can’t execute a full modern training strategy right away, but you can certainly start to apply some of the basic principles around what makes microlearning most successful in your current work. Fundamentals, like the idea of starting with a business goal and the science of learning, should be part of your current strategy and will set the stage for bigger improvements moving forward.

If you prefer a PDF edition of The Ultimate Guide to Microlearning (with a few extra tips and tricks!), fill out this form and we’ll send it your way!

"*" indicates required fields

Learn the main advantages of microlearning in the workplace.